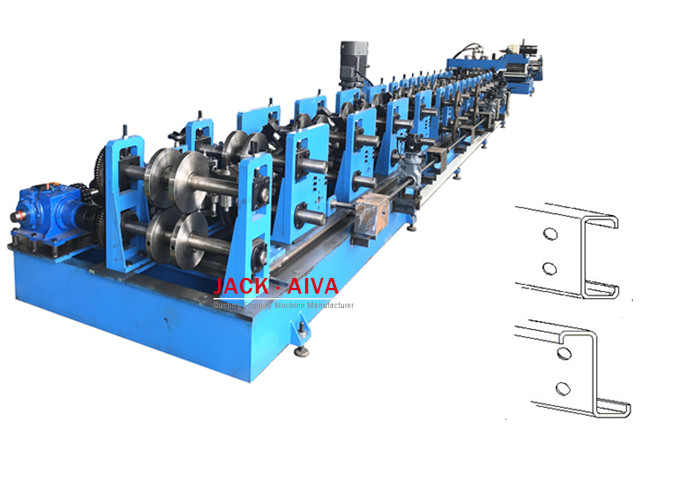

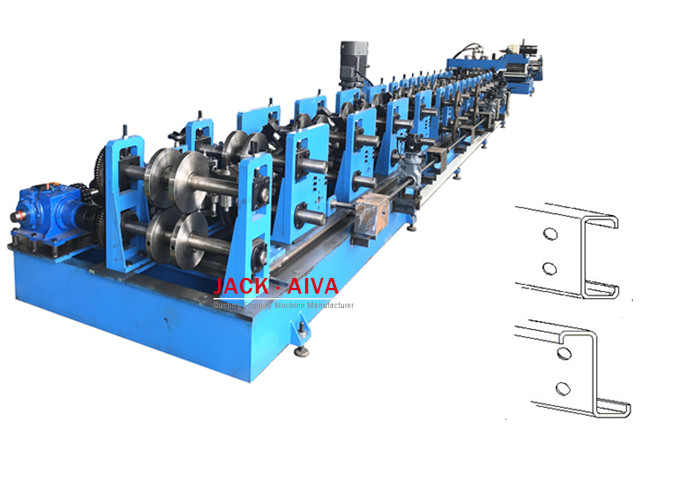

C-Z Purlin Roll Forming Machine

Cold Roll forming Machines for production the steel Structural frame products - C and Z purlins

C and Z Purlin is an integral part of light steel structure, Purlins and Girts

are roll-formed from Hi-Tensile Galvanised steel.

With the advantage of Cee & Zee purlin, widely adopted in Building

construction Industry – commercial and residential, they are

primarily used to provide lightweight, economical, efficient

roofing and cladding support systems for framed structures.

Roll Forming Machine Technology Specifications - C-Z purline auto

changeable

Our Manufacturer is one of the leading suppliers in china about the

C and Z section purline machine, The CZ Purlin production can be by

the same line and without any parts replacement when change the

different purline production.

The present roll forming machine is developed based on the original

one, that its technology from new Zealand. The same technology as

ASC CZ changeable production line. This is also the most developed

one in the world market.

The CZ profile width can be adjusted by hand wheel or servo motor

control. This can be selected by clients.

The following style is the high speed style CZ roll forming line.

The whole roll form line is consisted of de-coiler, material

feeding entrance, flatting device, holes punching equipments, main

roll forming machine, hydraulic cutting part, hydraulic system, PLC

control system and run out table, etc.

De-coiling---Coil sheet guiding and feeding---sheets Pre

cutting------cut-to-length----Roll forming---- Hydraulic punching

holes---cut to length—

stacking production

Main Parameters- C Z purlin Roll forming machine

| Feeding material Thickness: | 1.4-3mm (Q195, Q235) |

| Forming station: | 20 sets |

| Material of roller: | Quality moulds steel, polished and coated with chrome, hardness

HRC58-62 |

| Forming Roller Stations: | 20 Stations, quality casting steel after precision processed. |

| Main power: | 15KW |

| Hydraulic station power: | 5.5KW |

| Hydraulic pressure: | 10-12Mpa |

| Leveller | 4KW |

| Control system: | PLC Control with touch Screen, Inverter, Encoder are MITSUBISH or

Panasonic Brand Japan |

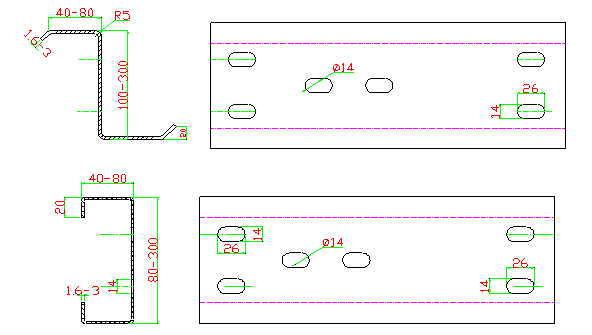

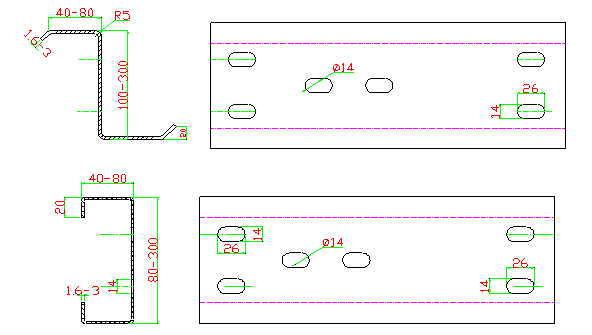

| C PURLIN: | Width:100-300mm; |

| High: 40-85mm |

| Z Purlin: | Width: 100-300mm |

| HIGH:40-85mm |

| Product length tolerance | 2M+/- 1.0mm |

| Line speed: | 10-15m/min (not including cutting material time) |

| Size of main machine: | 11000×1800×1800mm |

| Equipment weight: | 14000kg |

C Z purlin Section

- The manual decoiler or hydraulic decoiler can be optional.

- The normal driving system is controlled by chains. Gearing box with

cardan shaft also can designed according to your request.

- Standard C Z purlin profile drawing as following,

- We can send the best solution and design different style C & Z

Purlin roll forming machine according to client’s requirements,

such as holes punched after profile roll formed, or pre- punched,

etc. We can do a custom roll forming machine, i.e. we can design

the machine according to your specification and profile drawing.

Complex questions will be simple here.

Application - C Purline & Z Purlin

C PURLIN SECTIONS: C sections have flanges which are equal in size and are commonly

used for simple supported spans. C sections cannot be lapped

continuous spans in multi-bay buildings, but easily adapted for use

in small and medium sized buildings as structural framework.

Z PURLIN SECTIONS: Z sections are made with one flange broader than the other. When

one purlin is rotated 1800 two sections can be bolted together enabling them to be lapped.

Lapping the purlins over interior supports improves the load

capacity and rigidity of the purlins. Z sections may also be used

for simple spans. Purlins and Girts that are lapped form a

structurally continuous line along the length of the building